Truck stops are vital rest areas for drivers during their long-haul journeys. As bustling hubs of activity, it is crucial for truck stops to prioritize safety measures that create a secure environment for drivers and their valuable cargo.

In this blog, we will explore five major safety measures implemented at truck stops to ensure the well-being of drivers and minimize potential risks.

5 Major Safety Measures at Truck Stops

Understanding the following safety measures at truck stops will enhance your truck stop experience and provide peace of mind and ensure a secure environment for drivers:

1. Adequate Lighting

One of the primary safety measures at truck stops is the provision of adequate lighting throughout the premises. Well-lit areas contribute to a heightened sense of security by deterring potential criminal activity and promoting visibility. Illuminated parking lots, walkways, and fueling areas create a safer environment, allowing drivers to easily navigate and locate their vehicles.

2. Video Surveillance

Truck stops employ advanced video surveillance systems to monitor the premises and deter criminal activity. Strategically placed cameras provide continuous monitoring of parking lots, fueling areas, entrances, and other critical locations. Video surveillance acts as a deterrent to potential criminals and assists in identifying and resolving security incidents. The presence of surveillance systems fosters a sense of safety and provides valuable evidence in the event of any untoward incidents.

3. Security Personnel

Many truck stops have dedicated security personnel who patrol the premises, ensuring the safety of drivers and their vehicles. These professionals are trained to identify and address security concerns promptly. Security personnel provides a visible presence that deters criminal activities and provides assistance to drivers in need.

4. Secure Parking Areas

Truck stops offer designated parking areas that are specifically designed to accommodate heavy trucks. These parking areas often feature secure fencing, controlled entry points, and monitored access. By restricting access to authorized individuals only, truck stops minimize the risk of unauthorized entry and potential theft. Secure parking areas provide drivers with peace of mind, allowing them to rest and sleep without worrying about the safety of their vehicles and cargo.

5. Emergency Services and Communication

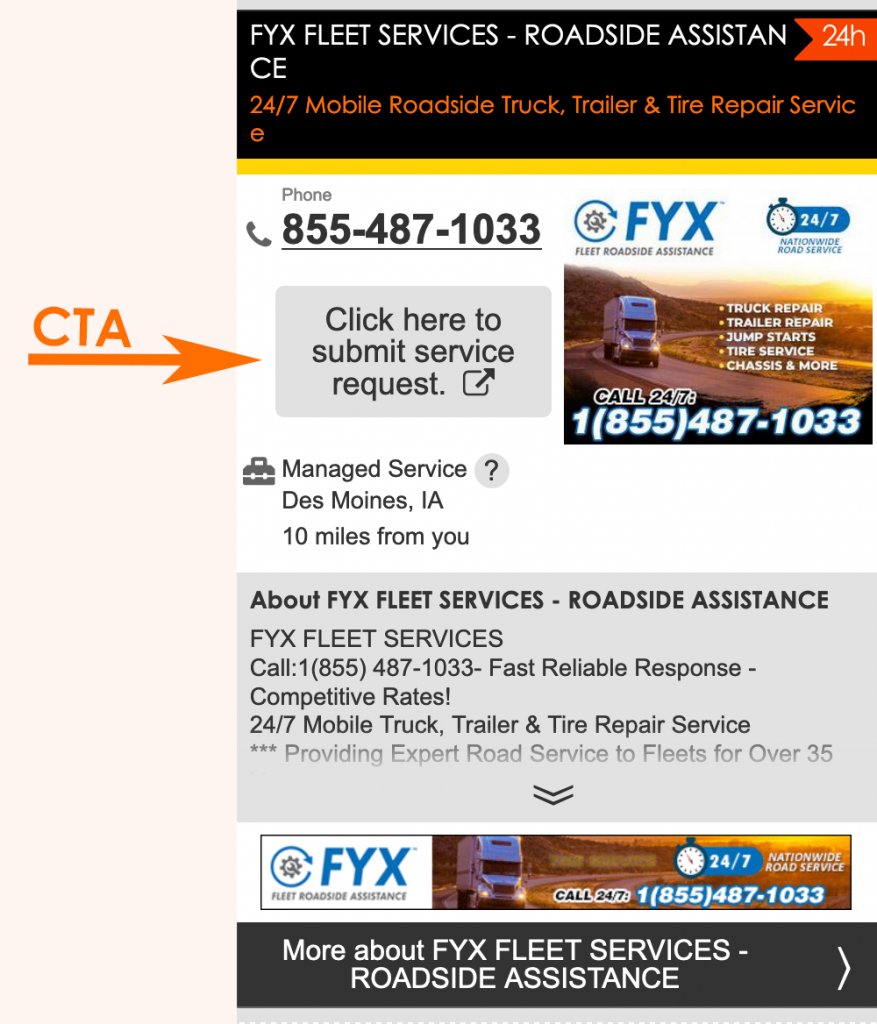

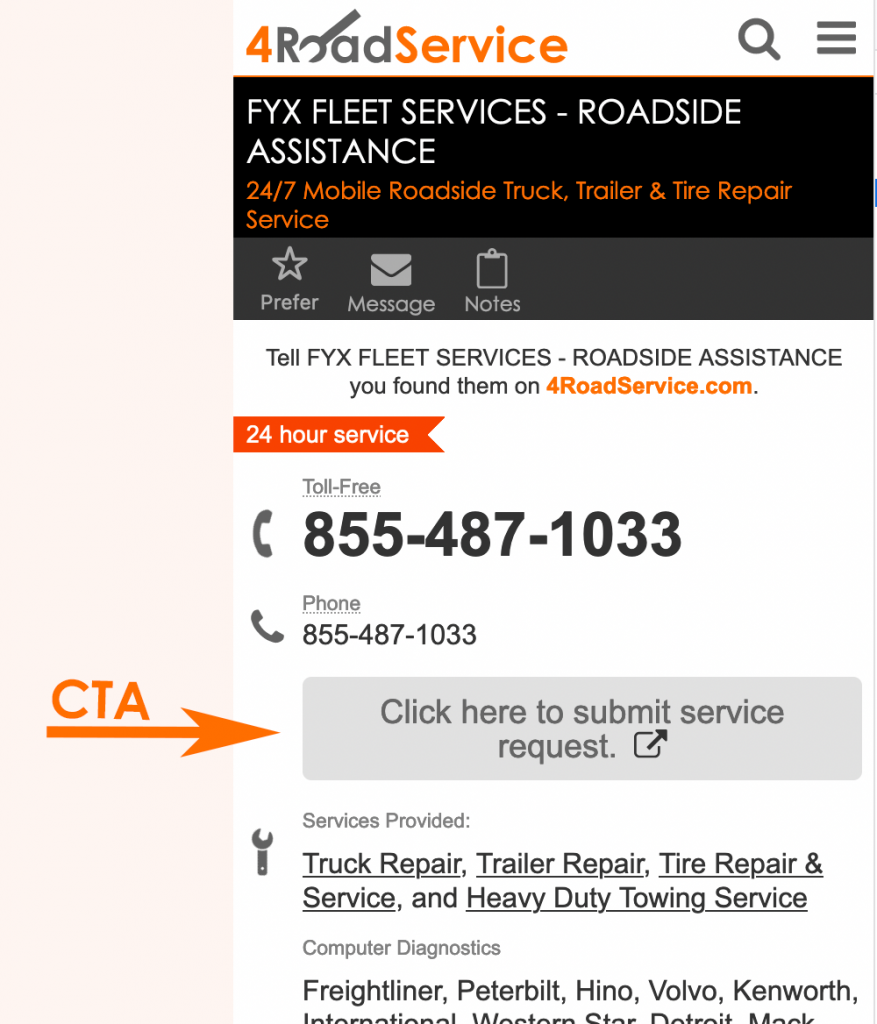

Truck stops prioritize emergency preparedness by providing access to emergency services and communication facilities. Many truck stops have dedicated emergency call boxes strategically located throughout the premises. These call boxes allow drivers to quickly summon assistance in case of emergencies or incidents requiring immediate attention.

Conclusion

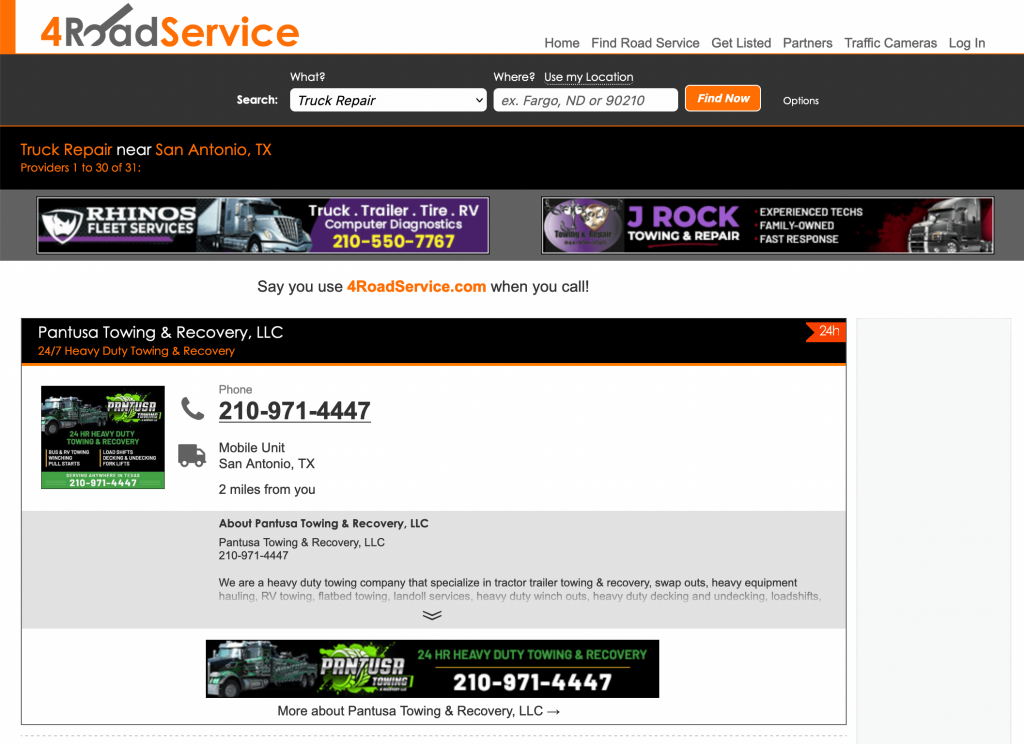

Truck stops take safety seriously and implement several key measures to ensure a secure environment for drivers. Adequate lighting, video surveillance, security personnel, secure parking areas, and access to emergency services and communication are all essential components of a well-rounded safety strategy. Whether you’re seeking a truck stop in Louisville, KY, or require heavy truck repair near you, understanding and utilizing these safety measures will contribute to a safer and more secure truck stop experience. Prioritizing safety at truck stops not only protects drivers and their valuable cargo but also fosters a sense of trust and confidence within the transportation industry as a whole.